Well today really sucked. Biggest disaster of the project so far but, a big learning experience. I drilled out the 10 bad rivets in the trailing edge. I had centered the bit on each rivet perfectly and got each rivet out without touching the hole. Some of my best drilling out to date. Except one small thing. As I was tapping the rivets out of the trailing edge, I was gradually bending THE ENTIRE TRAILING EDGE to the right side. I tried straightening it out but it looks like crap and I can tell even the end stiffeners are a little bent. I am calling the rudder a $400 practice kit. I know there are a lot of places I could have done better (even if they were in spec…I’m a bit a of a perfectionist). I decided to just order a new rudder and do it over. I started this project knowing full well this would probably happen at some point and maybe even again but at least I learned a valuable lesson early on. When hammering out the shank of drill out rivets, be sure the rest of the project is supported.

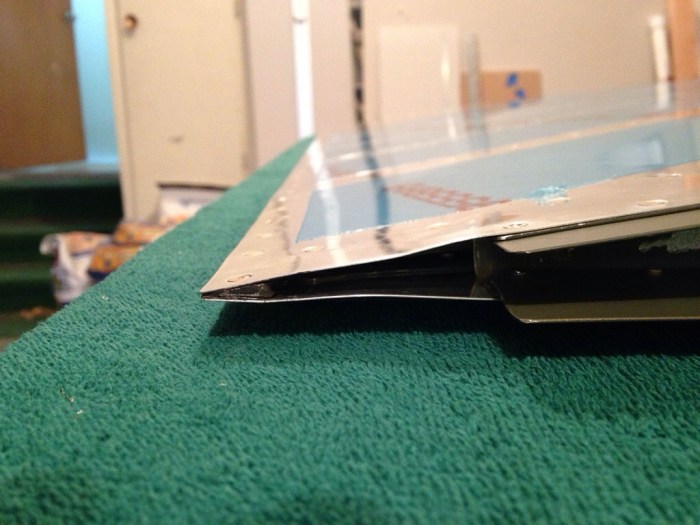

These pics were taken after I bent it back “straight.”

Here’s the bottom. You can even see that the stiffener is a little bent. Not gonna chance it.

And here’s the top.

FML!!